Harnessing Power: The Full Diode Bridge Rectifier's Role in AC/DC Conversion

Lgesemi: The operation of the full diode bridge rectifier, a crucial part in the conversion of alternating current (AC) to direct current (DC), is examined in this article. It describes how this rectifier produces a smooth DC output by effectively rectifying both half of the AC cycle using four diodes. Discover the benefits, features, and design of full diode bridge rectifiers as well as how they are used in a variety of power supplies and electronic devices.

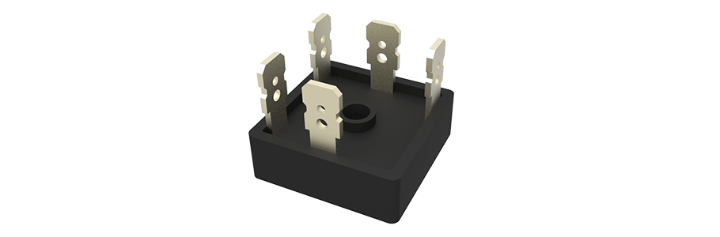

Introduction to Full Diode Bridge Rectifiers

A full diode bridge rectifier is a cornerstone of modern electronics, crucial for converting alternating current (AC) into direct current (DC). By employing four diodes in a bridge configuration, this circuit efficiently provides a DC output suitable for powering various devices. Its widespread application spans industries such as consumer electronics, industrial automation, and automotive systems, underscoring its importance in energy transformation and power management.

Understanding AC/DC Conversion

Alternating current and direct current serve distinct roles in electrical systems. While AC is ideal for power transmission due to minimal energy loss over long distances, DC is necessary for the operation of most electronic devices. A full diode bridge rectifier facilitates this transition by converting the fluctuating nature of AC into the steady, unidirectional flow of DC.

This AC-to-DC conversion process forms the backbone of power supplies, enabling devices like laptops, LED lights, and battery chargers to function seamlessly. The rectification process eliminates the negative voltage components of AC, transforming it into a usable form for circuits that require DC input.

The Significance of Rectifiers in Electronics

Rectifiers are indispensable in modern electronic systems. They ensure compatibility between AC power sources and DC-dependent devices. A full diode bridge rectifier is particularly significant due to its efficiency, simplicity, and ability to handle high power levels. It provides a robust solution for energy conversion, ensuring devices operate reliably without interruptions or damage.

Basic Operation of a Full Diode Bridge Rectifier

How a Bridge Rectifier Works

At its core, a full diode bridge rectifier utilizes four diodes arranged in a bridge configuration. During the positive half-cycle of the AC input, two diodes conduct, allowing current to flow through the load in one direction. During the negative half-cycle, the other two diodes take over, maintaining the same current direction through the load. This dual-phase rectification results in a pulsating DC output.

The Role of Each Diode in the Circuit

Each diode in the bridge rectifier plays a specific role:

- Positive Half-Cycle: Two diodes conduct (D1 and D3), guiding the current to the load.

- Negative Half-Cycle: The other two diodes (D2 and D4) take over, ensuring the load current remains unidirectional.

This complementary operation of diodes ensures maximum efficiency and minimal energy loss.

Circuit Configuration

Schematic Diagram of a Full Diode Bridge

A typical schematic for a full diode bridge rectifier includes:

- Four diodes forming the bridge

- An AC input source

- A load resistor to represent the device powered by the rectifier

- Optional components like capacitors for output smoothing

Component Arrangement and Connections

- The diodes are arranged in a diamond-like structure.

- The AC input terminals connect to the opposite ends of the bridge.

- The load connects to the output terminals, ensuring a consistent DC flow.

Advantages of Full Diode Bridge Rectifiers

Efficiency and Output Smoothness

The bridge rectifier offers higher efficiency compared to half-wave rectifiers, as it utilizes both halves of the AC waveform. Adding a capacitor or other filtering components can smooth the pulsating DC output, reducing ripples and enhancing performance.

Symmetric Operation and Reduced Ripple

Symmetric operation ensures balanced current flow, reducing the risk of component overheating. The reduced ripple effect makes the output stable, which is crucial for sensitive electronics.

Applications of Full Diode Bridge Rectifiers

Power Supplies for Electronics

The rectifier is widely used in AC adapters and power supplies for devices like televisions, mobile phones, and computers. Its ability to provide stable DC output ensures optimal device performance.

Industrial and Automotive Applications

Industrial automation systems and automotive electronics often rely on full diode bridge rectifiers for powering motors, sensors, and control circuits. Their robustness and reliability make them ideal for these demanding environments.

Advanced Topics in Rectifier Design

High-Frequency and High-Power Rectifiers

In high-frequency applications, such as switching power supplies, rectifiers must operate efficiently at elevated frequencies. Advanced designs incorporate specialized diodes like Schottky or silicon carbide (SiC) diodes to handle these conditions.

Custom Rectifier Solutions for Specific Needs

Custom rectifier designs are tailored for niche applications, balancing factors like size, efficiency, and thermal performance. Examples include rectifiers for renewable energy systems or compact devices requiring low heat dissipation.

Case Studies and Practical Examples

Real-World Implementations of Full Diode Bridge Rectifiers

- Solar Inverters: Used for converting solar panel AC output into DC for storage or further inversion to AC.

- Power Adapters: Common in household chargers for converting wall outlet AC into DC.

Lessons Learned from Practical Applications

Implementing full diode bridge rectifiers in real-world systems highlights the importance of component quality, thermal management, and proper filtering to achieve desired performance.

Conclusion

Recap of Key Points on Full Diode Bridge Rectifiers

The full diode bridge rectifier is an essential component in AC/DC conversion, offering efficiency, reliability, and versatility. Its role in powering modern electronics is unparalleled, with applications ranging from small gadgets to industrial systems.

The Future of Rectifier Technology

Emerging trends in power electronics, including wide-bandgap semiconductors and smart energy systems, promise continued innovation in rectifier technology. These advancements aim to enhance efficiency, reduce losses, and expand the capabilities of rectifiers in diverse applications.

FAQs

1. What is the primary purpose of a full diode bridge rectifier?

A full diode bridge rectifier converts alternating current (AC) into direct current (DC), providing a steady output for electronic devices. By utilizing all phases of the AC input, it ensures higher efficiency and smoother output compared to other rectifier types.

2. How does a full diode bridge rectifier differ from a half-wave rectifier?

A full diode bridge rectifier uses both halves of the AC waveform, resulting in a higher output voltage and reduced ripple. In contrast, a half-wave rectifier utilizes only one half of the AC cycle, leading to lower efficiency and greater ripple.

3. Can a full diode bridge rectifier handle high power applications?

Yes, full diode bridge rectifiers can handle high-power applications when designed with appropriate components. Using high-current diodes and incorporating heat sinks or advanced materials like silicon carbide can enhance performance in demanding environments.