Quality Assurance

Quality Management:

QC material selection, strict control of IPQC process, strict inspection of OQC shipment, strict entry control of incoming material inspection, worry free quality assurance through process inspection, and strict adherence to the final level of shipment inspection. The testing equipment is as follows:

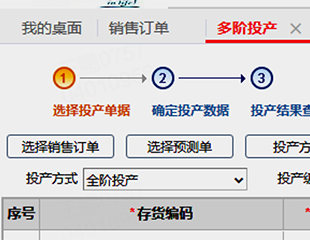

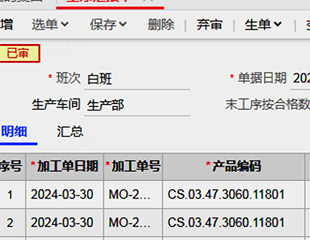

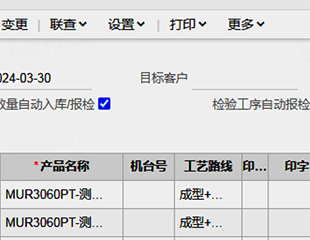

Systematic Production Management:

A multi-level production management mode is adopted for each batch of products, and detailed information is recorded for each process in the product production process. The product order, production processing, and sales shipment documents are all interrelated. The corresponding material model, batch, and operator of the product can be linked and queried through different documents, achieving product traceability; At the same time, any abnormal yield of each product can be detected in a timely manner, which facilitates timely measures to improve product quality.

Production Equipment:

Leading the forefront of technology, adhesive bonding machines, bonding machines, SMA chip solid crystal welding integrated machines, and SMA debonding molding integrated machines are all on the battlefield. From adhesive bonding to testing, the entire process is independently controlled to ensure the excellent performance of each product. Dust free purification, innovation driven, to create a comprehensive semiconductor production solution for you.

Experimental Equipment:

Professional power semiconductor device manufacturer, providing comprehensive experimental equipment solutions such as bridge stack high-temperature reverse bias aging system, diode high-temperature working life aging testing system, high-temperature and high humidity reverse bias aging testing system, etc. Leading the forefront of technology, creating excellent quality, and helping your products become more competitive!