How Can a Bridge Rectifier be Used to Power an LED?

Lgesemi: explores the use of a bridge rectifier to convert AC power into DC power suitable for driving an LED. The discussion covers the basic configuration of a bridge rectifier, the necessary components and connections for powering an LED, and potential considerations for efficient and safe operation. It also highlights the advantages and potential limitations of using a bridge rectifier for this purpose.

Introduction to Using Bridge Rectifier for LED Power

In the realm of electronics, powering devices with the appropriate type of electrical current is crucial. For Light Emitting Diodes (LEDs), which are typically designed to operate on Direct Current (DC), using an Alternating Current (AC) source requires a conversion process. This is where a bridge rectifier comes into play. A bridge rectifier is an essential component that converts AC to DC, making it possible to power LEDs from standard household AC outlets. In this article, we will delve into the intricacies of how a bridge rectifier can be used to power an LED, exploring its configuration, necessary components, and practical applications.

Definition and Importance

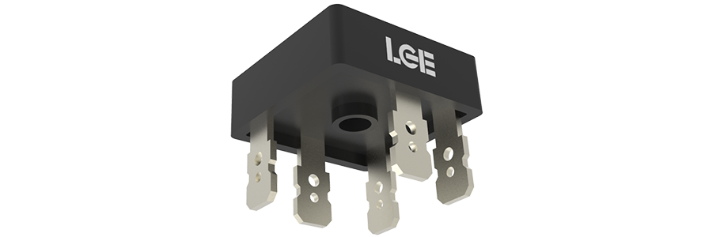

A bridge rectifier is an arrangement of four diodes in a bridge circuit configuration. It allows both halves of an AC waveform to be utilized, providing a smoother DC output compared to a half-wave rectifier. The importance of a bridge rectifier lies in its ability to efficiently convert AC power, which is readily available from power grids, into a usable DC form. This makes it an ideal solution for powering various DC devices, including LEDs.

LEDs have gained immense popularity due to their energy efficiency, long lifespan, and versatility in lighting applications. However, they require a stable DC voltage to function properly. Since most power sources provide AC, the use of a bridge rectifier becomes essential to ensure the LEDs receive the correct type of power. By converting AC to DC, the bridge rectifier enables the safe and efficient operation of LEDs, preventing potential damage caused by reverse polarity or fluctuating current.

Potential Applications and Advantages

The application of a bridge rectifier in powering LEDs extends across a wide range of fields. From residential lighting to industrial automation and even decorative lighting displays, the ability to convert AC to DC opens up numerous possibilities. Here are some key potential applications:

- Residential Lighting: Many modern homes utilize LED bulbs for their energy-saving properties. A bridge rectifier can be integrated into the lighting system to ensure a stable DC supply to the LEDs, enhancing their performance and longevity.

- Signage and Displays: LED signage and display screens often require a reliable DC power source. The bridge rectifier helps maintain consistent brightness and color accuracy by providing a steady DC voltage.

- Automotive Lighting: In vehicles, where the electrical system typically operates on DC, a bridge rectifier can still be useful in certain scenarios, such as when converting the vehicle's battery voltage for specific LED lighting applications.

- Industrial Control Systems: Industrial environments often use LED indicators and displays. The bridge rectifier ensures these components receive the correct DC power, even if the overall power supply is AC.

The advantages of using a bridge rectifier for powering LEDs are manifold:

- Efficiency: The full-wave rectification process of a bridge rectifier maximizes the utilization of the AC input, resulting in higher efficiency compared to half-wave rectifiers. This means less energy wastage and lower operating costs.

- Smooth DC Output: The bridge rectifier produces a smoother DC output by utilizing both halves of the AC waveform. This reduces ripple voltage, which can affect the performance and lifespan of the LEDs.

- Simplicity and Reliability: The design of a bridge rectifier is relatively simple, consisting of just four diodes. This simplicity makes it a reliable and cost-effective solution for power conversion.

- Versatility: Bridge rectifiers can handle a wide range of input voltages and currents, making them suitable for various LED applications with different power requirements.

Bridge Rectifier Configuration and Components

To understand how a bridge rectifier works in powering an LED, it is essential to grasp its basic configuration and the role of its components. A typical bridge rectifier consists of four diodes arranged in a bridge circuit formation. These diodes are usually made of semiconductor materials such as silicon or germanium.

The configuration involves connecting the four diodes in such a way that they form a closed loop, with two diodes conducting during each half cycle of the AC input. During the positive half cycle of the AC waveform, diodes D1 and D2 conduct, allowing current to flow through the load in one direction. In the negative half cycle, diodes D3 and D4 conduct, maintaining the same current direction through the load. This results in a pulsating DC output across the load.

In addition to the diodes, other components may be used in conjunction with the bridge rectifier to enhance its performance and protect the LEDs. These components include:

- Transformer: A transformer is often used to step down the high voltage AC from the power grid to a more manageable level suitable for the bridge rectifier and the LEDs. It also provides isolation between the mains supply and the low-voltage circuit, ensuring safety.

- Capacitor: A capacitor is connected across the output of the bridge rectifier to smooth out the pulsating DC signal. It charges during the peaks of the pulsating DC and discharges during the troughs, reducing the ripple voltage and providing a more stable DC supply to the LEDs.

- Resistor: A resistor may be used in series with the LEDs to limit the current flowing through them. This is important because LEDs are sensitive to current fluctuations, and exceeding their rated current can cause damage.

Detailed Circuit Diagram

To visualize the operation of a bridge rectifier in powering an LED, let's consider a detailed circuit diagram. The circuit consists of the following components:

- AC Source: This represents the power grid or any other AC power supply. It provides the input voltage and current to the circuit.

- Transformer: The primary winding of the transformer is connected to the AC source, and the secondary winding provides a stepped-down AC voltage.

- Bridge Rectifier: Four diodes (D1, D2, D3, and D4) are arranged in a bridge configuration. The AC input is connected to the two diagonally opposite ends of the bridge, and the DC output is taken from the other two diagonally opposite ends.

- Capacitor: A capacitor is connected across the output terminals of the bridge rectifier to smooth the DC signal.

- LED and Resistor: The LED is connected in series with a resistor to limit the current flowing through it. The anode of the LED is connected to the positive terminal of the smoothed DC output, and the cathode is connected to the negative terminal through the resistor.

When the AC voltage is applied to the input of the transformer, it is stepped down to a lower voltage level. This voltage is then fed into the bridge rectifier. During the positive half cycle of the AC waveform, diodes D1 and D2 conduct, allowing current to flow through the load (LED and resistor) in one direction. During the negative half cycle, diodes D3 and D4 conduct, maintaining the same current direction through the load. The result is a pulsating DC voltage across the load.

The capacitor connected across the output of the bridge rectifier charges during the peaks of the pulsating DC and discharges during the troughs, smoothing out the voltage fluctuations. This provides a more stable DC supply to the LED, ensuring its proper operation. The resistor limits the current flowing through the LED, preventing it from drawing excessive current and potentially damaging it.

By adjusting the values of the transformer, capacitor, and resistor, the circuit can be optimized to provide the desired DC voltage and current for the specific LED being used.

Role of Transformer, Diodes, and Capacitor (if used)

Each component in the circuit plays a crucial role in the process of powering an LED with a bridge rectifier:

- Transformer:

- Voltage Step-Down: The primary function of the transformer is to reduce the high voltage AC from the power grid to a level that is safe and suitable for the bridge rectifier and the LEDs. Most standard household AC outlets provide a voltage of around 120V or 240V, depending on the region. This voltage is too high for most LED applications and needs to be stepped down to a lower value, typically in the range of 5V to 20V.

- Isolation: The transformer provides electrical isolation between the mains supply and the low-voltage circuit. This is important for safety reasons, as it prevents any faults or surges in the mains supply from directly affecting the low-voltage side of the circuit.

- Diodes:

- Rectification: The four diodes in the bridge rectifier are responsible for converting the AC input into a pulsating DC output. They allow current to flow in only one direction during each half cycle of the AC waveform, effectively "rectifying" the AC signal.

- Full-Wave Rectification: By conducting during both halves of the AC cycle, the bridge rectifier achieves full-wave rectification. This results in a higher average output voltage compared to half-wave rectifiers, which only utilize one half of the AC cycle. Full-wave rectification also leads to a smoother DC output with less ripple voltage.

- Capacitor:

- Smoothing: The capacitor connected across the output of the bridge rectifier acts as a filter, smoothing out the pulsating DC signal. It stores electrical energy during the peaks of the pulsating DC and releases it during the troughs, thereby reducing the voltage fluctuations and providing a more stable DC supply to the LEDs.

- Ripple Reduction: The presence of the capacitor significantly reduces the ripple voltage in the DC output. Ripple voltage is the residual AC component present in the DC signal after rectification. High levels of ripple voltage can cause flickering or uneven brightness in LEDs. By smoothing out these fluctuations, the capacitor ensures a consistent and stable light output from the LEDs.

Practical Applications and Examples

To further illustrate how a bridge rectifier can be used to power an LED, let's consider a few practical examples:

Example 1: Simple LED Circuit for Home Lighting

In a simple home lighting application, a single white LED with a forward voltage drop of 3V and a desired operating current of 20mA is used. The steps to power this LED using a bridge rectifier are as follows:

- Determine Power Supply: Assume a standard household AC supply of 120V at 60Hz.

- Select Transformer: Choose a transformer with a secondary voltage of around 9V to account for voltage drops across the diodes and some headroom for the LED operation.

- Bridge Rectifier: Use a bridge rectifier module with four diodes capable of handling the expected current.

- Calculate Resistor Value: To limit the current through the LED to 20mA, calculate the series resistor value using Ohm's Law. The forward voltage drop across the LED is 3V, so the resistor should drop the remaining voltage (9V - 3V = 6V) at 20mA. R = V/I = 6V / 0.02A = 300Ω. Therefore, a 300Ω resistor is chosen.

- Connect Components: Connect the transformer secondary winding to the input of the bridge rectifier, and connect the output of the bridge rectifier to the LED in series with the resistor. Add a capacitor (e.g., 1000μF) across the output of the bridge rectifier to smooth the DC signal.

- Observe Operation: When the circuit is powered, the AC voltage from the mains is stepped down by the transformer, converted to DC by the bridge rectifier, smoothed by the capacitor, and limited in current by the resistor. The LED lights up with a stable brightness, indicating that it is receiving a proper DC supply.

This example demonstrates how a bridge rectifier can be used in a straightforward application to power a single LED for home lighting purposes. The same principles can be scaled up for multiple LEDs or more complex lighting systems by connecting multiple LED strings in parallel or series, as required.

Example 2: LED Strip Lighting for Decoration

LED strip lighting is commonly used for decorative purposes in homes, offices, and events. These strips typically consist of multiple LEDs connected in series and require a DC voltage of around 12V for proper operation. Here's how a bridge rectifier can be used to power such an LED strip:

- Identify Power Supply: Again, assume a standard household AC supply of 120V at 60Hz.

- Choose Transformer: Select a transformer with a secondary voltage of approximately 15V to account for voltage drops across the diodes and provide sufficient voltage for the LED strip.

- Bridge Rectifier: Use a bridge rectifier module suitable for the expected current draw of the LED strip. Ensure that the diodes can handle the maximum current required by the strip without overheating.

- Design Power Supply Circuit: Connect the transformer secondary winding to the input of the bridge rectifier. Add a capacitor (e.g., 2200μF) across the output of the bridge rectifier to smooth the DC signal and reduce ripple voltage. Also, include a fuse in series with the input of the transformer for protection against overcurrent conditions.

- Connect LED Strip: Connect the output terminals of the smoothed DC supply to the positive and negative terminals of the LED strip respectively. Make sure to follow the manufacturer's guidelines for wiring and polarity.

- Test and Adjust: Power up the circuit and observe the operation of the LED strip. If necessary, adjust the transformer ratio or add additional capacitors to further improve the stability of the DC output and ensure uniform brightness along the entire length of the strip. The use of a bridge rectifier in this example allows for a reliable and efficient conversion of AC power to DC power for the LED strip, providing consistent lighting performance without flickering or voltage fluctuations. It also enables easy integration with other control circuits, such as dimmer switches or microcontroller-based lighting systems, for enhanced functionality.

Powering an LED with a Bridge Rectifier: Considerations

Before implementing a bridge rectifier to power an LED, there are several important considerations to keep in mind:

- LED Specifications: Different types of LEDs have varying forward voltage drops and current requirements. It is crucial to know the exact specifications of the LED being used to select appropriate components for the power supply circuit, such as the transformer ratio, resistor value, and capacitor size. Exceeding the maximum forward current or voltage can damage the LED and shorten its lifespan.

- Heat Dissipation: The components in the power supply circuit, particularly the transformer and diodes, generate heat during operation. Proper heat dissipation measures should be taken to prevent overheating, which can lead to reduced efficiency and potential failure of components. Heat sinks or ventilation may be necessary depending on the power level and operating environment.

- Efficiency: While bridge rectifiers are relatively efficient in converting AC to DC, there are still some losses associated with the process. These losses include voltage drops across the diodes, copper losses in the transformer windings, and core losses in the transformer. Minimizing these losses can improve overall efficiency and reduce power consumption.

- Safety: Working with AC power involves inherent risks, especially when dealing with high voltages from the mains supply. It is essential to follow proper electrical safety practices, including using insulated tools, wearing protective gear, and ensuring that all connections are secure and properly insulated. Additionally, incorporating safety features like fuses and circuit breakers can help protect against electrical faults and hazards.

- Regulation and Compliance: Depending on the intended application and location, there may be regulatory requirements that need to be met when designing and using a power supply circuit for LEDs. For example, certain products may need to comply with electromagnetic compatibility (EMC) standards or safety certifications such as UL or CE. It is important to be familiar with these regulations and ensure that the design meets all applicable requirements.

Troubleshooting Common Issues

When using a bridge rectifier to power an LED, you may encounter some common issues. Here are their possible causes and solutions:

- LED Not Lighting Up:

- Possible Causes: Incorrect polarity connection of the LED; insufficient voltage or current supplied by the power circuit; open circuit or broken connection in the power delivery path; faulty LED or damaged component in the circuit.

- Solutions: Check the polarity of the LED connections and ensure they are correct. Measure the output voltage of the power supply circuit using a multimeter to verify that it is within the specified range for the LED. Inspect all connections for any loose or disconnected wires and repair as necessary. Test the LED with a known good power supply to check if it is functioning properly. If any component in the circuit is suspected to be faulty, replace it with a new one and retest the circuit.

- Flickering or Unstable Brightness:

- Possible Causes: Excessive ripple voltage in the DC output due to inadequate smoothing by the capacitor; insufficient capacitance value of the filter capacitor; variation in the input AC voltage (e.g., due to voltage fluctuations on the mains supply).

- Solutions: Increase the capacitance value of the filter capacitor to improve smoothing of the DC signal. For example, if a 1000μF capacitor is currently used, try increasing it to 2200μF or higher. Alternatively, add another smaller capacitor in parallel with the existing one to target high-frequency ripple components specifically. If voltage fluctuations on the mains supply are suspected, consider using a voltage regulator or stabilizer to maintain a more constant input voltage for the transformer.

- Overheating of Components:

- Possible Causes: Overloading the transformer by drawing too much current; inefficient design leading to excessive power dissipation in components; poor heat dissipation due to lack of proper cooling or ventilation; using components with inadequate power ratings for the given application.

- Solutions: Check the current draw of the load (LED) and ensure it does not exceed the rated capacity of the transformer. If necessary, upgrade to a transformer with a higher current rating. Review the circuit design for efficiency improvements, such as optimizing transformer winding ratios or selecting diodes with lower forward voltage drops. Ensure adequate heat dissipation by adding heat sinks to components that generate significant heat or improving ventilation around the circuit enclosure. Replace any components that have insufficient power ratings with ones that are more suitable for the application.

Key Takeaways

In summary, a bridge rectifier is an effective method for converting AC power to DC power to drive an LED. It offers several advantages, including simplicity, reliability, and efficiency, making it suitable for various applications where LED lighting is required. The key components involved in this process are transformers, diodes, resistors, and capacitors, each playing a specific role in ensuring stable and safe operation of the LED. By understanding how these components work together and considering factors such as LED specifications, heat dissipation, efficiency, safety, and regulatory compliance, one can design a robust power supply circuit for LEDs using a bridge rectifier. Troubleshooting common issues that may arise during implementation is also crucial to ensure optimal performance and longevity of both the LED and the power supply circuit. With proper design and attention to detail, bridge rectifiers can provide a dependable solution for powering LEDs in diverse applications ranging from simple indicator lights to complex lighting systems.