How to Perform Bridge Rectifier Testing?

Lgesemi: will provide a comprehensive guide on how to test a bridge rectifier, covering the necessary tools and equipment, step-by-step testing procedures, and interpretation of test results. It will also discuss common issues and troubleshooting tips related to bridge rectifier failures.

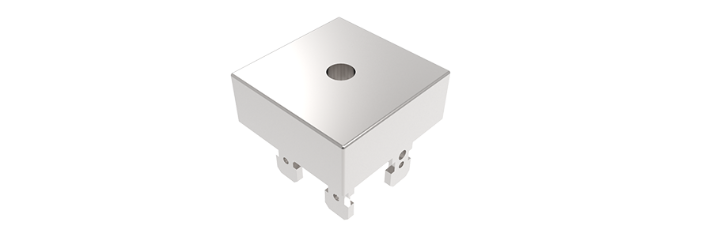

Introduction to Bridge Rectifier Testing

Bridge rectifiers are crucial components in many electronic devices, converting alternating current (AC) to direct current (DC). Proper testing of these components ensures the reliability and longevity of electronic circuits. This article provides a comprehensive guide on how to test a bridge rectifier, covering the necessary tools and equipment, step-by-step testing procedures, and interpretation of test results. It will also discuss common issues and troubleshooting tips related to bridge rectifier failures.

Overview of Bridge Rectifier Functionality

A bridge rectifier consists of four diodes arranged in a bridge configuration, allowing both halves of the AC waveform to be utilized, resulting in a smoother DC output. The primary function of a bridge rectifier is to convert AC input into DC output, which can then be used by various electronic devices. Understanding this functionality is essential for effective testing and troubleshooting.

Importance of Testing in Electronics Maintenance

Regular testing of bridge rectifiers is vital in electronics maintenance. It helps identify potential issues before they lead to complete failure, ensuring the continuous operation of electronic systems. Testing also aids in maintaining efficiency, reducing energy consumption, and preventing costly repairs or replacements. By incorporating regular tests into maintenance routines, technicians can extend the lifespan of their equipment and improve overall performance.

Testing Equipment and Tools

To perform accurate bridge rectifier testing, specific tools and equipment are required:

- Multimeter: A versatile instrument for measuring voltage, current, and resistance. A digital multimeter with diode testing capability is preferred.

- Oscilloscope: For visualizing the waveform and analyzing phase relationships. A dual-channel oscilloscope is ideal.

- Power Supply: To provide a stable AC input for testing purposes.

- Load Resistor: Used during load testing to simulate real-world conditions.

- Screwdrivers and Soldering Kit: For accessing and desoldering components if necessary.

Multimeter and Oscilloscope Setup

Multimeter Setup

- Select the Appropriate Measurement Mode: Set the multimeter to measure DC voltage for output terminal measurements and AC voltage for input verification.

- Diode Test Mode: Use the diode test mode to check the forward voltage drop across each diode in the bridge rectifier.

Oscilloscope Setup

- Connect Probes: Attach the oscilloscope probes to the input and output terminals of the bridge rectifier.

- Calibrate: Ensure the oscilloscope is calibrated for accurate readings.

- Set Time Base and Voltage Scale: Adjust these settings to capture the entire waveform clearly.

Power Supply and Load Configuration

Power Supply

- Connect the Power Supply: Attach the power supply to the AC input terminals of the bridge rectifier.

- Adjust Voltage Settings: Set the power supply to deliver the appropriate AC voltage as specified by the device's requirements.

Load Configuration

- Connect the Load Resistor: Attach the load resistor to the DC output terminals.

- Calculate Load: Determine the appropriate resistance value based on the expected output current and voltage.

Step-by-Step Testing Procedures

Visual Inspection and Preparation

- Visual Check: Inspect the bridge rectifier for any visible signs of damage, such as burnt components or loose connections.

- Preparation: Ensure the circuit is de-energized before proceeding with any tests. Disconnect the power supply and discharge any capacitors.

DC Voltage Measurement Across Output Terminals

- Measure DC Output Voltage: Using the multimeter, measure the DC voltage across the output terminals of the bridge rectifier. Compare this reading with the expected voltage.

- Check for Consistency: Ensure the voltage remains stable over time, indicating proper functioning of the rectifier.

AC Input Voltage Verification

- Measure AC Input Voltage: With the power supply connected, measure the AC voltage at the input terminals using the multimeter.

- Compare Readings: Verify that the AC input voltage matches the specifications provided by the power supply.

Load Testing and Efficiency Measurement

- Apply Load: Connect the load resistor and power on the circuit.

- Measure Output Voltage Under Load: Record the DC output voltage while the load is applied.

- Calculate Efficiency: Use the formula Efficiency = (Output Power / Input Power) * 100% to determine the efficiency of the bridge rectifier.

Interpreting Test Results

Identifying Normal and Abnormal Voltage Readings

- Normal Readings: The DC output voltage should be within the expected range, typically close to the peak value of the AC input voltage minus the diode forward voltage drops.

- Abnormal Readings: Significant deviations from the expected voltage may indicate a faulty component, such as a shorted or open diode.

Analyzing Waveforms and Phase Relationships

- Waveform Analysis: Observe the waveform on the oscilloscope. A healthy bridge rectifier should produce a smooth DC output with minimal ripple.

- Phase Relationships: Check the phase relationships between the input and output signals. Any irregularities may suggest issues with the diodes or other components.

Conclusion

In summary, testing a bridge rectifier involves several critical steps, including visual inspection, voltage measurements, and waveform analysis. By following these procedures and interpreting the results accurately, technicians can diagnose and address issues effectively, ensuring the reliable operation of electronic systems.

Recommendations for Preventive Maintenance and Monitoring

- Regular Testing: Schedule periodic tests to monitor the health of bridge rectifiers and other critical components.

- Environmental Control: Maintain optimal operating conditions, such as temperature and humidity, to reduce stress on electronic components.

- Training: Ensure technicians are well-trained in testing procedures and interpretation of results.

- Documentation: Keep detailed records of all tests and maintenance activities for future reference and trend analysis.

FAQs

What are the common causes of bridge rectifier failure?

Bridge rectifiers can fail due to various reasons, including overheating, overvoltage, reverse polarity, and physical damage. Prolonged exposure to high temperatures can degrade the internal components, leading to reduced efficiency and eventual failure. Overvoltage conditions can cause excessive current flow, damaging the diodes. Reverse polarity can result in incorrect operation and potential damage. Physical damage, such as cracks or broken solder joints, can also affect performance.

How often should bridge rectifiers be tested?

The frequency of testing depends on the application and operating conditions. In general, it is recommended to test bridge rectifiers annually or whenever there is a change in operating conditions, such as an increase in temperature or load. However, in critical applications where reliability is paramount, more frequent testing may be necessary.

Can a faulty bridge rectifier be repaired?

In most cases, a faulty bridge rectifier cannot be repaired and must be replaced. The components are typically integrated into a single package, making individual diode replacement impractical. However, if the issue is identified early and limited to a specific diode, it may be possible to replace only that component. Always consult the manufacturer's guidelines and seek professional assistance when dealing with complex repairs.