Navigating the World of Electronic Components Supply: Your Ultimate Guide

Lgesemi: In today's fast-paced tech environment, the network that supplies electronic components is crucial in crafting our digital future. Every gadget, from phones to smart cities, depends on a complex web of suppliers, makers, and distributors to deliver the latest technology. With 15 years in the industry, I've seen both the hurdles and chances that come with navigating this detailed system. This thorough guide will take you deep into the realm of electronic parts supply, discussing its subtleties, current trends, and top practices to keep you one step ahead.

The lifeline of the tech sector is undoubtedly its supply chain for electronic parts, which fuels innovation and growth throughout our digital universe. It's a precise balancing act between supply and demand, where even the smallest hiccup can cause widespread effects globally. Recall the significant chip shortage in 2021? That incident highlights just how vital this supply chain is to our contemporary way of life.

But don't worry! Whether you're well-versed in the field or just starting out, this guide will provide you with the essential knowledge and insights needed to succeed in this ever-changing industry. We'll cover everything from the fundamental types of components to the advanced trends influencing the future of electronics. So, get ready for an exciting adventure through the world of electronic component supply!

1. Introduction to the Electronic Components Supply Chain and Its Importance

You're holding your smartphone, a marvel of modern technology. But have you ever wondered about the journey each tiny component inside it has taken to reach your hands? That's where the electronic components supply chain comes in – it's the intricate network that brings these technological wonders to life.

The Backbone of Innovation

The electronic components supply chain is like the nervous system of the tech industry. It connects manufacturers, suppliers, distributors, and end-users in a complex web of relationships. Without this system, our gadgets would be nothing more than pipe dreams.

Think about it – every resistor, capacitor, and microchip has to be designed, manufactured, tested, and delivered with precision. It's a logistical ballet that requires perfect timing and coordination. One misstep, and entire production lines can grind to a halt.

Global Impact and Economic Significance

Let's talk numbers for a second. The global electronic components market was valued at a whopping $382.16 billion in 2021, and it's projected to reach $538.32 billion by 2026. That's not just big business – it's the engine driving technological progress worldwide.

But it's not just about the money. This supply chain impacts everything from national security to environmental sustainability. Countries are vying for dominance in semiconductor production, recognizing it as a key to economic and technological supremacy.

Challenges and Opportunities

Now, I won't sugarcoat it – navigating this world can be tough. Supply chain disruptions, geopolitical tensions, and rapid technological advancements keep us on our toes. But with challenges come opportunities. Those who can adapt quickly and innovate will thrive in this dynamic environment.

Remember the chip shortage I mentioned earlier? It taught us valuable lessons about resilience and diversification. Companies are now rethinking their strategies, focusing on building more robust and flexible supply chains.

2. An Overview of Different Types of Electronic Components Commonly Sourced

Alright, let's roll up our sleeves and dive into the nitty-gritty of electronic components. Trust me, understanding these building blocks is crucial for anyone in the industry. It's like knowing your ABCs before writing a novel!

Active Components: The Energizers

Active components are the life of the party in any electronic circuit. They can control electrical currents and typically require a power source to function. Let's break them down:

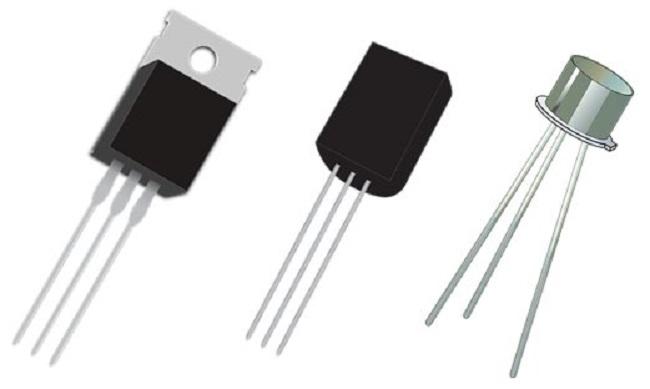

Transistors: These little powerhouses are the workhorses of modern electronics. They amplify or switch electronic signals and are the foundation of all modern computing. Fun fact: The first transistor was about the size of a palm; now, billions can fit on a single chip!

Integrated Circuits (ICs): Also known as microchips, these are the brains of our devices. They can contain millions of transistors, resistors, and capacitors in a tiny package. From simple logic gates to complex microprocessors, ICs come in all shapes and sizes.

Diodes: Think of these as one-way streets for electricity. They allow current to flow in one direction while blocking it in the other. LEDs (Light Emitting Diodes) are a popular type of diode that's revolutionized lighting technology.

Passive Components: The Unsung Heroes

Passive components might not have the glamour of their active counterparts, but they're absolutely essential for circuit function. They don't require a power source and can't control current by themselves.

Resistors: These components resist the flow of electric current. They're used to control voltage and current levels in circuits. Ever noticed those colored bands on cylindrical components? That's a resistor!

Capacitors: Think of these as tiny batteries that can store and release electrical energy quickly. They're crucial for filtering, timing, and energy storage in circuits. From the humble electrolytic capacitor to the high-tech supercapacitor, these components come in various types and sizes.

Inductors: These coiled wonders store energy in a magnetic field when current flows through them. They're essential in filters, power supplies, and wireless communication circuits.

Electromechanical Components: Bridging the Physical and Electrical Worlds

These components have both electrical and mechanical functions:

Switches and Relays: They control the flow of electricity by physically opening or closing circuits. From the simple light switch in your home to complex industrial relays, these components are everywhere.

Connectors: These unsung heroes ensure proper connections between different parts of a circuit or between devices. From USB ports to industrial-grade connectors, they come in countless varieties.

Sensors: These clever devices convert physical phenomena (like temperature, pressure, or light) into electrical signals. They're the eyes and ears of our smart devices, enabling everything from touchscreens to autonomous vehicles.

3. Strategies for Selecting the Right Supplier Based on Quality, Cost, and Reliability

Alright, folks, this is where the rubber meets the road. Choosing the right supplier can make or break your project. It's like picking a dance partner – you need someone who can keep up with your rhythm and won't step on your toes!

Quality: The Non-Negotiable Factor

When it comes to electronic components, quality isn't just a nice-to-have – it's absolutely crucial. A single faulty component can lead to device failures, recalls, and damaged reputations. Here's how to ensure you're getting top-notch quality:

Certifications Matter: Look for suppliers with recognized certifications like ISO 9001 for quality management. These aren't just fancy pieces of paper; they indicate a commitment to maintaining high standards.

Sample Testing: Don't be shy about requesting samples. Put them through rigorous testing to ensure they meet your specifications. Remember, a stitch in time saves nine!

Traceability: Can your supplier provide detailed information about the origin and manufacturing process of their components? This is crucial for identifying and addressing any issues that might arise.

Cost: Balancing the Books

We all love a good deal, but in the world of electronic components, the cheapest option isn't always the best. Here's how to approach cost considerations:

Total Cost of Ownership (TCO): Look beyond the sticker price. Consider factors like shipping costs, potential tariffs, and the cost of potential failures or recalls.

Volume Discounts: If you're planning large orders, negotiate volume discounts. But be cautious – don't commit to more than you need just to get a lower price.

Payment Terms: Flexible payment terms can be as valuable as a lower price. A supplier who offers favorable terms might be worth a slightly higher component cost.

Reliability: The Long Game

In this fast-paced industry, you need a supplier who'll be there for you through thick and thin. Here's what to look for:

Track Record: How long has the supplier been in business? What do their other clients say about them? Don't be afraid to ask for references.

Communication: A good supplier should be responsive and transparent. If they're dodging your questions now, imagine how they'll behave when issues arise.

Flexibility: Can they adapt to changes in your order volume or specifications? In today's volatile market, flexibility is worth its weight in gold.

The Secret Sauce: Building Relationships

Here's a pro tip from my years in the industry: the best supplier relationships are partnerships, not just transactions. Invest time in building rapport with your suppliers. Share your long-term plans with them. The more they understand your business, the better they can serve you.

Remember that time during the chip shortage when I needed a hard-to-find component? It was my long-standing relationship with a supplier that saved the day. They went above and beyond to source it for me, even when larger customers were clamoring for the same part.

4. Trends and Technologies Shaping the Future of Electronic Components Supply

Buckle up, folks! We're about to take a roller coaster ride into the future of electronic components supply. Trust me, it's going to be one heck of a journey!

The Rise of AI and Machine Learning

Artificial Intelligence isn't just for sci-fi movies anymore. It's revolutionizing the electronic components supply chain:

Predictive Analytics: AI algorithms are getting scary good at predicting demand fluctuations and potential supply chain disruptions. It's like having a crystal ball, but way more accurate!

Quality Control: Machine learning is enhancing defect detection in component manufacturing. I've seen systems that can spot imperfections the human eye would miss, reducing defect rates dramatically.

Inventory Management: AI-powered systems are optimizing inventory levels, reducing waste, and improving cash flow. It's like having a super-smart inventory manager working 24/7.

The Internet of Things (IoT) Revolution

The IoT is not just changing the types of components we need; it's transforming how we manage the supply chain:

Smart Warehouses: IoT sensors are creating hyper-connected warehouses, tracking components in real-time. No more lost shipments or inaccurate inventory counts!

Condition Monitoring: Sensitive components can now be monitored for temperature, humidity, and shock during transit. It's like having a babysitter for your most delicate parts.

Demand Sensing: IoT devices are providing real-time data on component usage, allowing for more accurate demand forecasting. It's like having a direct line to your customers' needs.

Sustainability: The Green Revolution

Sustainability isn't just a buzzword; it's becoming a key driver in the industry:

Eco-friendly Materials: There's a growing push for components made from sustainable or recyclable materials. I've seen amazing innovations in biodegradable electronics!

Energy Efficiency: Components that consume less power are in high demand, driven by the need for longer battery life and reduced energy costs.

Circular Economy: There's an increasing focus on designing components for easy recycling and reuse. It's not just good for the planet; it's good for business too.

Blockchain: Bringing Transparency to the Supply Chain

Blockchain technology is set to revolutionize supply chain transparency:

Counterfeit Prevention: Blockchain can create an unalterable record of a component's journey from manufacturer to end-user, making it nearly impossible to introduce counterfeit parts.

Compliance Tracking: With increasing regulations around component sourcing (think conflict minerals), blockchain offers a foolproof way to demonstrate compliance.

Smart Contracts: Automated, blockchain-based contracts could streamline procurement processes, reducing paperwork and speeding up transactions.

5G and Beyond: The Connectivity Revolution

The rollout of 5G (and the development of 6G) is creating new demands and opportunities:

High-Frequency Components: There's a growing need for components that can handle the high frequencies used in 5G and future networks.

Miniaturization: As devices pack in more features, there's a push for ever-smaller components that can handle increased power and data throughput.

Edge Computing: The shift towards edge computing is driving demand for specialized components that can process data closer to the source.

5. Conclusion with Actionable Tips for Navigating the Complex World of Electronic Components Supply Effectively

Whew! What a journey we've been on, exploring the ins and outs of the electronic components supply chain. Now, let's bring it all together with some actionable tips to help you navigate this complex world like a pro.

Embrace Flexibility and Adaptability

If there's one thing I've learned in my 15 years in this industry, it's that change is the only constant. The ability to pivot quickly can be your superpower:

Diversify Your Supplier Base: Don't put all your eggs in one basket. Having multiple suppliers for critical components can save your bacon when disruptions hit.

Stay Informed: Keep your finger on the pulse of industry trends. Subscribe to reputable industry publications, attend trade shows, and network with peers. Knowledge is power!

Invest in Agile Systems: Implement flexible inventory management and procurement systems that can adapt to changing conditions quickly.

Leverage Technology Wisely

Technology is your friend in navigating the complex world of electronic components supply:

Implement AI-Driven Forecasting: Use predictive analytics to anticipate demand fluctuations and potential supply chain disruptions.

Explore Blockchain for Transparency: Consider implementing blockchain solutions for better traceability and counterfeit prevention.

Embrace IoT for Real-Time Insights: Implement IoT solutions in your warehouses and logistics for real-time visibility into your supply chain.

Build Strong Relationships

In this industry, your network can be your net worth:

Cultivate Supplier Partnerships: Don't just transact; build relationships. Regular communication and mutual understanding can lead to preferential treatment when supplies are tight.

Engage with Industry Associations: Join relevant industry associations. They're great sources of information and can provide valuable networking opportunities.

Collaborate with Competitors: Yes, you read that right! Sometimes, collaborating with competitors on non-competitive issues (like lobbying for favorable regulations) can benefit everyone.

Prioritize Sustainability

Sustainability isn't just good for the planet; it's becoming a business imperative:

Audit Your Supply Chain: Regularly assess your supply chain for sustainability. Look for opportunities to reduce waste and improve energy efficiency.

Consider Eco-Friendly Alternatives: Explore components made from sustainable materials. They might cost more upfront, but they can pay off in terms of customer goodwill and regulatory compliance.

Plan for Circularity: Think about the entire lifecycle of your products. How can you design them for easy recycling or reuse?

Frequently Asked Questions

1. How can I ensure the authenticity of electronic components in my supply chain?

Ensuring the authenticity of electronic components is crucial to maintain product quality and reliability. Here are some strategies I've found effective:

Source from Authorized Distributors: Always prioritize purchasing from authorized distributors or directly from manufacturers. They have established relationships with component makers and can guarantee authenticity.

Implement Rigorous Testing: Invest in advanced testing equipment and procedures. X-ray inspection, electrical testing, and decapsulation can help identify counterfeit parts.

Use Traceability Tools: Implement serialization and traceability systems. Technologies like blockchain can create an unalterable record of a component's journey through the supply chain.

Train Your Team: Educate your procurement and quality control teams on how to spot potential counterfeits. They should be familiar with common counterfeiting techniques and red flags.

Leverage Industry Resources: Utilize databases like ERAI (Electronic Resellers Association International) that track counterfeit incidents and suspect suppliers.

Remember, the cost of implementing these measures is far less than the potential damage from counterfeit components. I once saw a company lose millions due to a single batch of fake capacitors. Don't let that be you!

2. What strategies can I use to mitigate supply chain disruptions in the electronic components industry?

Supply chain disruptions are an unfortunate reality in our industry, but there are ways to minimize their impact:

Diversify Your Supplier Base: Don't rely on a single source for critical components. Having multiple suppliers in different geographic regions can provide a buffer against localized disruptions.

Implement Buffer Stock: Maintain a strategic inventory of critical components. While this ties up capital, it can be a lifesaver during shortages.

Develop Alternative Components: Work with your engineering team to qualify multiple components for each function. This gives you flexibility when specific parts become unavailable.

Use Predictive Analytics: Leverage AI and big data to forecast potential disruptions and demand fluctuations. This allows you to take proactive measures.

Foster Strong Supplier Relationships: Build partnerships with your key suppliers. Good relationships can lead to preferential treatment during shortages.

Consider Vertical Integration: For critical components, consider bringing production in-house or investing in suppliers to have more control over the supply chain.

Stay Informed: Keep abreast of global events that could impact the supply chain. Natural disasters, geopolitical tensions, and regulatory changes can all cause disruptions.

In my experience, a combination of these strategies provides the best protection. During the recent chip shortage, companies that had diversified suppliers and maintained buffer stocks were able to weather the storm much better than those who didn't.

3. How is the trend towards miniaturization affecting the electronic components supply chain?

The drive towards miniaturization is reshaping our industry in fascinating ways:

Increased Complexity in Manufacturing: Producing smaller components requires more advanced and precise manufacturing techniques. This has led to a consolidation in the supplier base, as only larger companies can afford the necessary equipment.

Changes in Packaging and Handling: Smaller components are more delicate and require specialized handling and packaging. This has implications for storage, transportation, and assembly processes.

New Quality Control Challenges: Inspecting and testing miniaturized components requires more sophisticated equipment and techniques. We're seeing a rise in the use of AI and machine vision in quality control.

Impact on Design: Miniaturization allows for more functionality in smaller devices, but it also presents challenges in thermal management and signal integrity. This is driving innovation in materials and design techniques.

Supply Chain Visibility: Tracking smaller components through the supply chain can be more challenging. This is driving adoption of advanced tracking technologies like RFID and IoT sensors.

Inventory Management: Smaller components mean more units can be stored in the same space, but they're also easier to misplace. This is leading to investments in automated storage and retrieval systems.

Recycling and Sustainability Challenges: Miniaturization can make it harder to separate and recycle components at the end of a product's life. This is spurring research into new recycling technologies and design-for-recycling approaches.

From my perspective, miniaturization is both a challenge and an opportunity. It's pushing us to innovate in every aspect of the supply chain, from manufacturing to logistics to recycling. Companies that can adapt to these changes will be well-positioned for the future.