The Industry, Technical Status, and Prospects of SiC Schottky Diodes

Lgesemi: Shenzhen Luguang Electronic Technology Co., Ltd. is committed to the development of China's semiconductor power device manufacturing industry and providing high-quality semiconductor power device products and professional services to global power device consumers.

Although the application of MOSFET products is rapidly expanding and is the focus of manufacturers' research and development activities, the commercial application of SiC power devices is still mainly based on Schottky diodes. Now, combining the application and the device itself, we will introduce the technical characteristics, obstacles, and future development trends of SiC Schottky diodes.

Market Status and Challenges

1. Cost

The biggest obstacle to the widespread application of SiC devices at present is still cost. It can be said that if the cost of SiC power devices can be reduced to a level close to that of silicon devices, many problems can be easily solved, rather than the current situation. At present, the market price of the most typical SiC Schottky diode product (600V10A) is still 5 to 6 times higher than that of the same specification silicon FRD product. For products with larger rated currents, the cost gap becomes even more significant. In fact, due to the small market size, the vast majority of the few SiC device manufacturers currently do not have sufficient production capacity resources and are subsidizing at a loss, and cannot guarantee a large supply. Therefore, whether to reduce costs and ensure supply is the biggest question downstream application manufacturers have for device manufacturers. Until a satisfactory answer is obtained to this question, the application of SiC Schottky diodes is limited to a few essential fields. There are four typical aspects.

(1) High end audio system

Mainly utilizing the excellent high-temperature and high-power amplification functions of SiC transistors (BJT, JFET, MOSFET) to achieve the best audio and auditory effects with minimal distortion and high fidelity. But there is also a clear demand for SiC Schottky diodes, which can be used in different circuit parts. This is an industry that pursues performance and user experience, and is not sensitive to cost. It is the first civilian downstream field of SiC Schottky diodes (and also SiC power devices), which provided the initial cash flow for SiC power device manufacturers in the early days. Due to the lack of high-end audio manufacturing industry in our country and the late start in the SiC device industry, we have not been able to have the opportunity to enter this market.

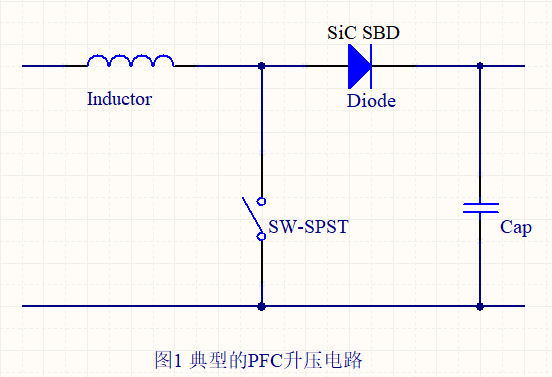

(2) Server Power Factor Correction (PFC)

This is mainly because a large number of servers are centrally placed, which consumes high power, and at the same time, the silicon fast recovery diode (FRD) generates high heat. After switching to SiC SBD, efficiency is improved not only by reducing power consumption, but more importantly by lowering device temperature, reducing heat dissipation costs, and enhancing critical system reliability. Before the rise of new energy vehicles, server power PFC was once the main market for SiC SBD. This application field has high requirements for reliability and has already been occupied by European, American, and Japanese companies. Domestic manufacturers have difficulty penetrating due to their late start. Figure 1 is a typical PFC boost circuit diagram.

Mainly because the micro inverters used in household photovoltaics have a smaller volume and require an increase in operating frequency to reduce the volume of passive components. At high frequencies, the efficiency of silicon FRD decreases. Some countries and regions (such as the European Union, California, Australia, etc.) have efficiency restrictions on photovoltaic micro reverse grid connection, which is roughly around 95%, making SiC SBD a necessary choice. The SiC SBD used in photovoltaic micro inverters has a lower power level, ideal application conditions (circuit environment), and lower requirements for the electrical environment reliability of the product. The product quality and cost are relatively easy to meet the requirements. This is currently the main source of profit for SiC device manufacturers. Once household solar energy is popularized through policy support and other means, the SiC power device industry will inevitably have explosive development.

(4) Portable electric vehicle charger PFC

This application is considered similar to photovoltaic micro inverters, with the difference being that there are no regulatory restrictions on the lower limit of efficiency. However, due to the space occupation and weight load of new energy vehicles, the demand for small and lightweight is more urgent, so SiC SBD is widely used. Correspondingly, fixed charging stations with less consideration for space and quality limitations have lower penetration rates for SiC SBD. At present, electric vehicle chargers are in an explosive growth stage, and there is a strong demand for domestically produced SiC devices, which is a market opportunity that domestic manufacturers must seize.