Unlocking Precision: Guide to Crystal Oscillator Circuits

Lgesemi: This comprehensive manual explores the complexities of crystal oscillator schematics, giving readers a clear grasp of how these precise timing instruments operate. Learn about the fundamental elements, design ideas, and real-world uses of crystal oscillators in a range of electronic systems. This extensive resource will assist you in becoming an expert in the field of crystal oscillator circuit design, regardless of your background—engineer, hobbyist, or student.

Introduction to Crystal Oscillators

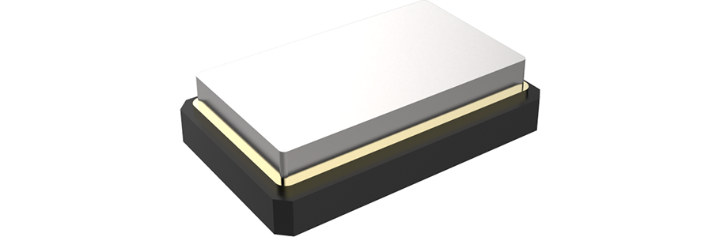

Overview of Crystal Oscillators

Crystal oscillators, ubiquitous yet often overlooked, are the pulsating hearts of countless electronic systems, providing the precise temporal references that underpin modern technology. Their ability to generate remarkably stable and accurate frequencies stems from the exploitation of a fascinating phenomenon: the piezoelectric effect in crystalline quartz. This intricate interplay between mechanical stress and electrical charge forms the foundation of these indispensable components, enabling applications spanning from the global positioning system to the humble wristwatch.

A Historical Trajectory Marked by Innovation

The genesis of crystal oscillators can be traced back to the nascent days of electronics in the early 20th century, a period marked by fervent exploration of the physical world. The discovery of piezoelectricity in quartz crystals—the curious ability of these crystalline structures to generate an electrical potential in response to mechanical deformation—laid the groundwork for a technological revolution. Subsequent decades witnessed a relentless refinement of these devices, driven by the insatiable demands of emerging technologies. From bulky, temperature-sensitive early iterations to the miniature, highly stable temperature-compensated crystal oscillators (TCXOs) and oven-controlled crystal oscillators (OCXOs) of today, the evolution of crystal oscillator technology mirrors the broader trajectory of electronics itself, a testament to human ingenuity.

Deconstructing the Crystal Oscillator Schematic: A Symphony of Components

A deep understanding of the crystal oscillator's schematic diagram is paramount for anyone seeking to harness its power. Beyond the seemingly simple representation lies a complex interplay of components, each playing a crucial role in sustaining stable oscillations. The quartz crystal, the heart of the circuit, acts as a highly selective resonant element, dictating the fundamental frequency. However, the crystal alone is insufficient. Amplifying elements, typically transistors or integrated circuits, provide the necessary gain to overcome inherent losses and maintain oscillation. Feedback networks, carefully designed to satisfy the Barkhausen stability criterion, ensure that the oscillations persist at the desired frequency. Furthermore, load capacitors, often overlooked, play a critical role in impedance matching and frequency stability. The interplay of these elements, meticulously orchestrated, transforms a simple collection of components into a precision timekeeping device. Moreover, the nuances of different oscillator topologies, from the Pierce oscillator with its elegant simplicity to the more complex Colpitts and Clapp configurations, offer a rich tapestry of design choices, each with its own performance characteristics and trade-offs. Truly grasping the intricacies of these circuits requires not just a superficial understanding of the components, but a deep appreciation for their dynamic interactions.

Basic Circuit Components

- Quartz Crystal: The heart of the oscillator, responsible for generating the oscillations.

- Amplifier: Typically an operational amplifier or transistor-based circuit that sustains the oscillations.

- Feedback Network: Ensures the proper phase shift required for sustained oscillations.

- Capacitors: Used to tune the frequency and stabilize the oscillator.

- Resistors: Help in controlling the gain and stability of the circuit.

Oscillator Types (XO, VCXO, TCXO, OCXO)

There are several types of crystal oscillators, each designed for specific applications:

- Standard Crystal Oscillator (XO): The most common type, used in general-purpose applications requiring stable frequency output.

- Voltage Controlled Crystal Oscillator (VCXO): Allows for frequency tuning via an applied voltage, useful in applications requiring adjustable frequencies.

- Temperature Compensated Crystal Oscillator (TCXO): Uses additional temperature sensing elements to maintain frequency stability over varying temperatures.

- Oven Controlled Crystal Oscillator (OCXO): Incorporates an oven to keep the quartz crystal at a constant temperature, providing the highest level of frequency accuracy and stability.

Designing Crystal Oscillator Circuits

Designing a crystal oscillator circuit involves careful selection of components and meticulous attention to detail. Key considerations include the choice of quartz crystal, the design of the feedback network, and the overall layout of the circuit.

Schematic Diagrams and Layout

When creating a schematic diagram, it's important to clearly label all components and show the connections between them. Proper layout ensures minimal interference and optimal performance. For instance, placing capacitors close to the quartz crystal can help reduce noise and enhance stability.

Frequency Stability and Accuracy

One of the primary advantages of crystal oscillators is their high frequency stability and accuracy. This is achieved through precise control of component values and careful design practices. For example, using low-drift capacitors and high-quality resistors can significantly improve the performance of the oscillator.

Crystal Oscillator Applications

Far from mere components, crystal oscillators form the pulsating heart of countless systems, their resonant frequencies orchestrating the symphony of modern technology. Their influence spans from the mundane ticking of a digital clock to the complex choreography of global telecommunications networks, highlighting their critical role in maintaining temporal order and signal integrity.

Synchronization's Silent Guardians: In the realm of telecommunications, data streams, fragmented and encoded, rely on the unwavering precision of crystal oscillators. These unassuming devices provide the foundational reference signals, ensuring that the intricate dance of modulation and demodulation remains synchronized across vast distances, bridging continents and connecting disparate corners of the world. Without their steady hand, the coherent transmission of information would descend into chaotic noise.

Temporal Precision in the Digital Age: The relentless march of time, as perceived by our digital companions, is dictated by the resonant vibrations of quartz crystals. Whether embedded within the silicon heart of a supercomputer or driving the display of a humble wristwatch, crystal oscillators provide the rhythmic pulse that underpins accurate timekeeping. Their consistent frequency output, a testament to the predictable nature of piezoelectric resonance, ensures that temporal accuracy persists across extended periods, preventing digital drift and maintaining the integrity of time-sensitive operations.

Industrial Harmony through Controlled Oscillation: Within the demanding environments of industrial automation, where precision and reliability reign supreme, crystal oscillators provide the unwavering heartbeat of complex control systems. From the precise movements of robotic arms to the intricate coordination of sensor networks, their stable oscillations ensure that operations proceed smoothly and efficiently. Their resilience in the face of harsh conditions – extreme temperatures, mechanical vibrations, and electromagnetic interference – makes them indispensable components in mission-critical industrial applications.

Navigating the Labyrinth of Oscillator Maintenance: The longevity and performance of these critical components are not guaranteed; they demand diligent maintenance and astute troubleshooting. Frequency drift, a subtle but insidious deviation from the intended resonance, can be induced by temperature fluctuations or the inevitable aging of components. Signal loss, a more abrupt disruption, may stem from faulty connections or damaged components. Addressing these issues proactively, through the strategic replacement of aging capacitors with low-drift alternatives or the implementation of temperature compensation techniques, is crucial to prevent cascading system failures.

Extending the Lifespan of Resonance: Maximizing the operational lifespan of crystal oscillators requires a nuanced understanding of their vulnerabilities. Shielding them from environmental extremes – excessive heat, biting cold, and pervasive humidity – is paramount. Regular inspections, focusing on potential points of weakness such as solder joints and connectors, can preempt failures. Meticulous cleaning of contacts further safeguards performance, ensuring the unimpeded flow of electrical signals.

Delving into the Art of Oscillator Design: Beyond the practicalities of maintenance lies the intricate world of oscillator design. Advanced techniques, such as temperature compensation and ultra-low phase noise design, push the boundaries of performance. Temperature compensation, a sophisticated form of dynamic control, employs sensors and intricate circuitry to counteract the destabilizing effects of temperature variations, ensuring consistent frequency output regardless of environmental fluctuations. Ultra-low phase noise design, a pursuit of ultimate stability, minimizes the inherent jitter in the oscillator's output signal, making these specialized devices ideal for high-precision applications like satellite communication and scientific instrumentation, where even the slightest deviations can have profound consequences.

Case Studies and Practical Examples

Real-World Applications

One practical example is in GPS technology where ultra-stable oscillators are used to synchronize signals with atomic clocks ensuring pinpoint location accuracy. Another example is in medical equipment where precise timing is critical for diagnostic devices and treatment machines.

Design Challenges and Solutions

Designing crystal oscillators for space missions presents unique challenges due to extreme temperatures and radiation levels. Engineers overcome these by using specialized materials and shielding techniques to protect the oscillators while maintaining their precision.

In conclusion, understanding the intricacies of designing maintaining, and troubleshooting crystal oscillator circuits is crucial for anyone involved in electronics. From basic principles to advanced applications, this guide provides comprehensive insights into maximizing the performance and longevity of these essential components.

Frequently Asked Questions

Q1: What is the difference between a standard crystal oscillator and a temperature compensated crystal oscillator?

A1: A standard crystal oscillator (XO) operates at a stable frequency under controlled conditions but may experience drift due to temperature variations. In contrast, a temperature compensated crystal oscillator (TCXO) incorporates additional circuitry to counteract temperature-induced frequency changes, making it more suitable for applications where frequency stability over a wide temperature range is critical.

Q2: How does a voltage controlled crystal oscillator work?

A2: A voltage controlled crystal oscillator (VCXO) allows for dynamic adjustment of its output frequency by applying a control voltage to a varactor diode within the oscillator circuit. The varying capacitance of the varactor diode alters the resonant frequency of the crystal, enabling fine-tuning of the output frequency according to the applied voltage.

Q3: Why is frequency stability important in crystal oscillators?

A3: Frequency stability is crucial because it ensures consistent performance and reliability of electronic systems. In applications like communication networks, timing systems, and data transmission, any deviation from the intended frequency can lead to signal degradation, synchronization issues, or even system failure. High frequency stability helps maintain precision and coherence across various operations.